Longlasting. Versatile. Coverage.

Benefits of aluminium composite.

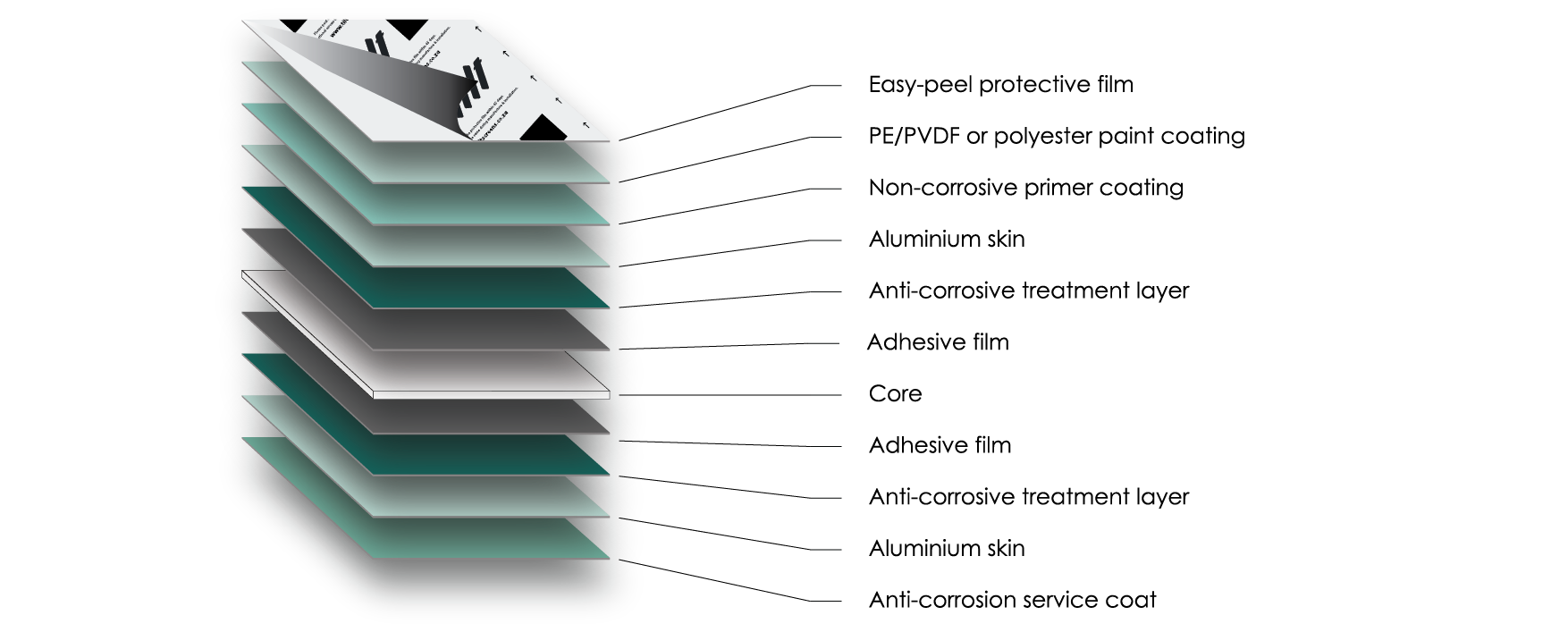

Material selection is key to reaching the best results for your project. With our expert knowledge, we will make technical recommendations and proposals to ensure the right decision is made. Aluminium composite material (ACM) is a modern architectural material with the potential to make any building unique.

ACM has become one of the most versatile, customisable and affordable products in the industry. Ideal for both new builds and the rehabilitation or renovation of existing sites, its aesthetic capacity is beyond any other construction cladding material on the market.

Long Lasting.

Structural strength & durable composition to withstand harsh outdoor environments.

Flatness.

Rigid and resistant. Excellent surface flatness and levelling on mass surfacing & coverage.

Mass Finishes.

Visual consistency. Guaranteed quality finishes throughout whole batch manufacture.

Efficiency.

Can add benefits of thermal & acoustical insulation qualities to a building.

Light-Weight.

Efficient to CNC machine & requires less structure to install on large volumes.

Versatile.

Available with or without pattern. Both very large or very small apertures possible.

Some applications.

External facades and cladding.

Interior cladding and skylights.

Architectural trims and eyebrow features.

Column cladding, power pole and beam wraps.

External staircase cladding and concealment.

Retail cladding & shopfront wraps.

Balcony sunscreens and privacy screens.

AC covers and tank concealment.

Guardhouse and entrance features.

Eaves cladding and exterior ceiling panelling.

AC covers and pool pump concealment.

Internal screens and partitions.

Lobby ceilings and lift cladding.

Reception desk cladding & desk privacy screens.

Internal wall cladding and wall features.

Signage and pylon billboards.

References.